Aeroseal Success at The Auckland International Airport

Econair Services Limited approached LIMS Aeroseal to seal and certify three runs of ducting in WP2 (Work Package Two) at the Auckland International Airport. We were able to help our customer attain satisfactory airtightness on all counts due to the innovative nature of the Aeroseal nanotech compound and applicators. LIMS Aeroseal performed seventeen seals/certifications at the Auckland International Airport.

Project Overview

Client: Econair Services Limited

Reporting to: Josh Brunton (Mechanical Engineer)

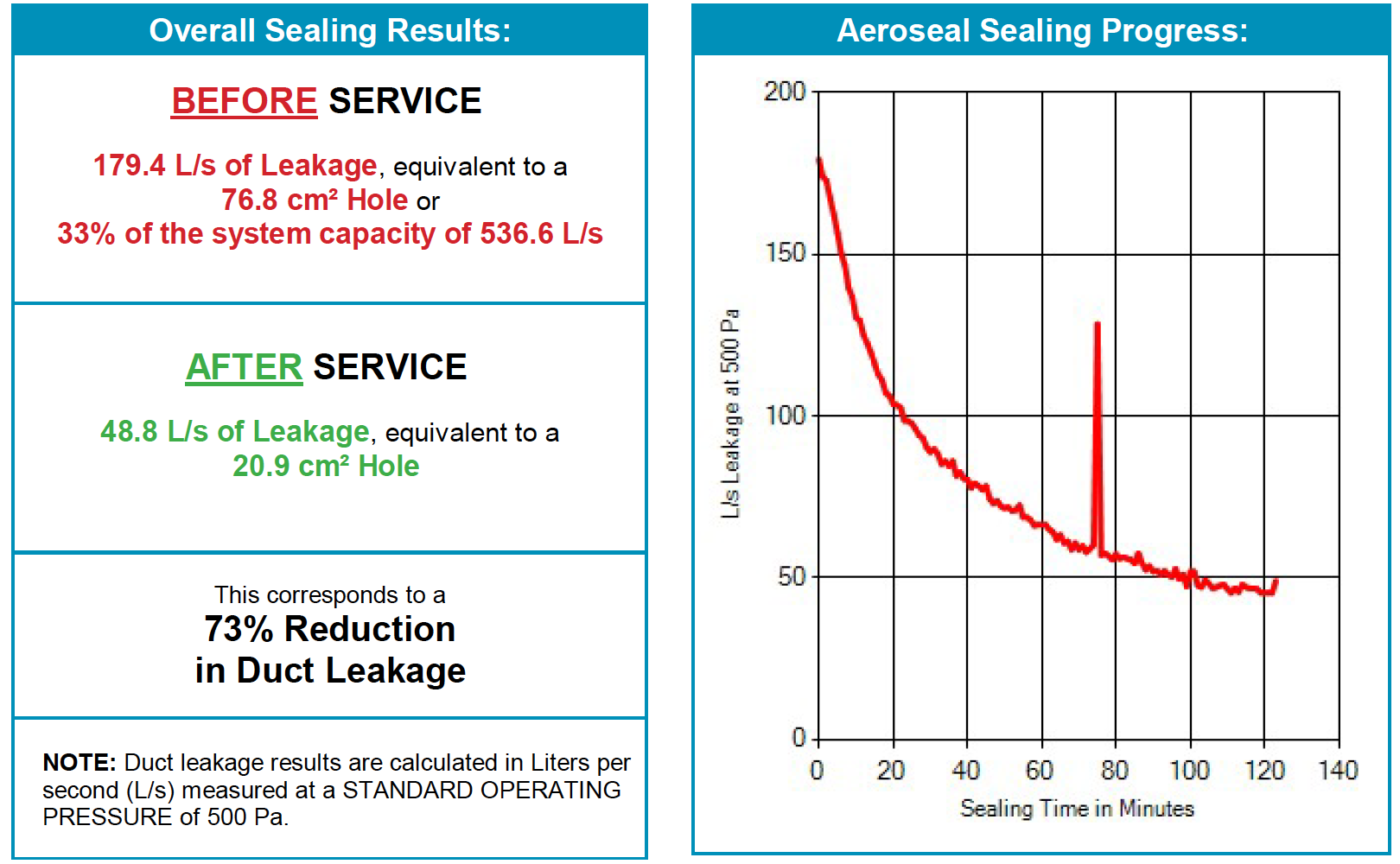

Initial Scope: Seal and certify airtightness on three ductwork runs in the Arrivals Hall under construction. The target was to reduce leakage below 50L/s at an operating pressure of 500Pa.

Expanded Scope: Over the course of six engagements, LIMS Aeroseal performed 17 sealing events across various duct sections with tolerances ranging from 171L/s to 55L/s. Every tested section was brought into compliance by project completion on 28 March 2025.

Key Figures

- Lead Hand: Lucas Scott James, 2IC LIMS Aeroseal

- Technician: Alan Baird, OG

- Initial Contact: Michael Gilmore (Project Manager)

- Site Coordination: Jonathan Fa’asalele (Site Manager)

Timeline and Execution

The project began with a purchase order issued on 29 July 2024. While initial engagements were brief one- or two-day affairs, the major push occurred over fifteen consecutive business days starting on 28 February 2025. During this period, our team worked tirelessly to meet expanded scope requirements and ensure airtight compliance across all duct sections.

Challenges and Achievements

The acceptable leakage tolerances ranged widely, from as high as 171L/s down to the stringent target of 55L/s. Using Aeroseal technology, we successfully sealed every duct section to meet or exceed these requirements. This achievement underscores the effectiveness of Aeroseal in tackling even the most demanding projects.

- The ductwork for AHU-T2-16 Service Spine has a measured leakage rate of 57l/s which is below the calculated maximum allowable leakage of 205l/s. This was measured with a test pressure of 503 Pa.

- The ductwork for AHU-T2-16 Plenum has a measured leakage rate of 55l/s which is below the calculated maximum allowable leakage of 58 l/s. This was measured with a test pressure of 500 Pa.

- The ductwork for AHU-T2-16 Plenum has a measured leakage rate of 55l/s which is below the calculated maximum allowable leakage of 58 l/s. This was measured with a test pressure of 500 Pa.

- The ductwork for AHU-T2-16 Plenum has a measured leakage rate of 55l/s which is below the calculated maximum allowable leakage of 58 l/s. This was measured with a test pressure of 500 Pa.

- The ductwork for AHU-T2-81 Immigration has a measured leakage rate of 23l/s which is below the calculated maximum allowable leakage of 35l/s. This was measured with a test pressure of 501 Pa.

- The ductwork for AHU-T2-81 Return has a measured leakage rate of 44 /s which is below the calculated maximum allowable leakage of 119l/s. This was measured with a test pressure of 506 Pa.

Conclusion

Completing WP2 at Auckland International Airport was a milestone for LIMS Aeroseal. Not only did we help Econair Services Limited meet industry standards for ductwork airtightness, but we also demonstrated the scalability and reliability of Aeroseal technology in high-profile projects. With the terminal forecasted for completion in mid-2025, our contribution ensures optimal performance and energy efficiency for years to come.

This project exemplifies how LIMS Aeroseal continues to set benchmarks for innovation and quality in duct sealing solutions. We look forward to future opportunities where we can bring our expertise to similar large-scale ventures!

To Learn More About Improving The Comfort, Indoor Air Quality, and Energy Efficiency Of Your Building Call 0226759426 or Email info@aeroseal.nz